Asbestos-containing materials are still present in many buildings throughout California. These legacy materials, once used in insulation, floor tiles, fireproof coatings, and textured ceilings, pose a serious health risk when disturbed. Without proper asbestos abatement best practices, asbestos fibers can become airborne and put building occupants, employees, and the general public at risk.

Whether you're renovating a structure, managing a commercial site, or responding to an emergency contamination issue, it's critical to follow established asbestos regulations at every stage of the project.

Key Takeaways:

An asbestos survey is required before demolition or remodeling begins.

EPA guidelines and OSHA laws mandate strict removal and air protection measures.

Abatement workers must be trained and wear proper personal protective equipment.

Air monitoring is the final step in confirming site safety and regulatory compliance.

Partnering with a licensed contractor protects workers and reduces liability.

Why Following Asbestos Abatement Best Practices Matters

Long-term asbestos exposure can lead to devastating health outcomes, including mesothelioma, asbestosis, and lung cancer. These illnesses often result from inhaling airborne asbestos fibers, which are invisible to the naked eye. Once disturbed, even a small amount of asbestos-containing material can contaminate an entire building’s air system.

Federal regulations from the EPA and OSHA require that employers take proactive steps to prevent exposure in the workplace. Property owners and contractors who ignore asbestos removal protocols not only endanger human health, but they also face steep penalties and stop-work orders.

Step-by-Step Breakdown of Safe Abatement Procedures

1. Conduct a Certified Asbestos Survey

Before any demolition, renovation, or construction project begins, a certified asbestos inspector must conduct a thorough asbestos survey. This process includes collecting samples of suspect building materials, such as old insulation, duct wrap, and wallboard, and sending them to an accredited lab for analysis.

A proper demolition survey identifies all asbestos-containing materials so that building owners can make informed decisions. Skipping this step violates EPA rules and puts workers at risk of exposure.

2. Prepare the Work Site with Containment Measures

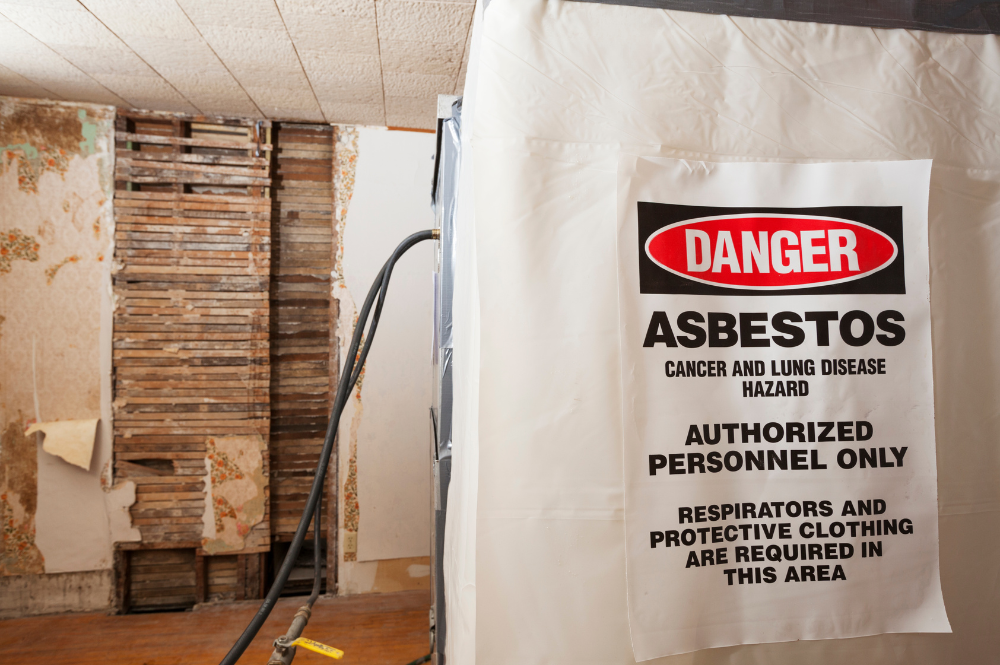

Once asbestos is confirmed, the job site must be prepped to prevent contamination. Contractors use plastic sheeting to enclose the area, seal off ventilation systems, and deploy negative air pressure units to keep fibers from escaping into adjacent spaces. Warning signs are posted to limit access to authorized personnel only.

Additional safety and health measures, such as setting up clean rooms, sealing immobile items, and labeling all asbestos waste, are essential to avoid contamination beyond the work zone.

3. Equip Workers with Personal Protective Equipment

All personnel involved in asbestos abatement must be trained in occupational safety and wear full personal protective equipment. This includes disposable suits, gloves, boots, and respirators equipped with HEPA filters. Proper donning and doffing procedures help prevent accidental spread of fibers beyond the containment zone.

OSHA mandates this level of protection, especially in environments where asbestos-containing materials are being actively disturbed or removed.

4. Execute the Asbestos Removal

Certified teams use wet methods and specialized tools to safely remove asbestos products without releasing fibers into the air. Materials are kept damp, carefully cut, bagged in leak-tight containers, and labeled per federal requirements. All asbestos waste is transported to qualified landfills that accept regulated hazardous materials.

HCI Environmental’s crews follow strict protocols for documenting each phase of removal, which protects both the employer and building occupants from future liability.

5. Conduct Final Air Monitoring and Clearance Testing

Once the area is cleaned and all visible materials have been removed, third-party professionals perform air monitoring using high-efficiency particulate air (HEPA) sampling devices. This ensures the space meets established clearance limits before reoccupancy.

Without clearance results, building access should remain restricted. Air testing provides critical documentation to demonstrate compliance with federal agencies and ensures the workplace is safe for employees and the public.

Partnering with a Qualified Abatement Contractor

Licensed asbestos contractors understand the complex web of asbestos regulations issued by state and federal agencies. At HCI Environmental, our team brings extensive experience in large-scale abatement projects, including schools, commercial buildings, and government facilities.

We manage the process end-to-end, from site surveys and permitting to removal, air testing, and final reporting. Our commitment to asbestos abatement best practices keeps your project compliant, cost-effective, and safe for everyone involved.

Using Additional Resources for Ongoing Compliance

Maintaining a safe building doesn’t end with one removal project. It’s essential to stay informed through training programs, updates from federal agencies, and expert guidance. HCI Environmental offers other resources including regulatory updates, on-site training, and full-service hazardous material management.

Our goal is to help clients develop cost-effective strategies that protect both human health and long-term property value. From small residential buildings to large commercial campuses, we provide scalable support that evolves with your project needs.

Keeping Safety at the Forefront

Safe asbestos removal starts with the right process and the right partner. From demolition surveys to post-removal air monitoring, HCI Environmental provides full-service abatement that meets all OSHA and EPA standards. Our team is trained, licensed, and ready to help protect your site, your people, and your reputation.

Contact us today to schedule your asbestos survey or learn more about our abatement services.

Frequently Asked Questions

What is an asbestos survey, and when is it required?

An asbestos survey identifies the presence of asbestos-containing materials in a building before any demolition or renovation work. It is required under both federal and state asbestos regulations.

Why is personal protective equipment necessary during abatement?

Personal protective equipment safeguards workers against airborne asbestos fibers, which can cause severe respiratory illnesses.

How does air monitoring work after asbestos removal?

Air monitoring involves using HEPA sampling equipment to test for residual asbestos fibers. It's the final step in confirming a safe, reoccupiable environment.

What role do OSHA and the EPA play in asbestos regulations?

OSHA and the EPA set standards that govern every step of the asbestos abatement process, from removal methods to disposal. We stay current with these agencies so our clients remain protected.

What should I do if I suspect asbestos materials in my building?

Avoid disturbing the material and contact a certified asbestos professional immediately. Even minor exposure can present health risks. Our team can inspect the site and provide next steps to ensure safety.

24/7 EMERGENCY CHEMICAL SPILL RESPONSE LIVE OPERATOR 800.988.4424

24/7 EMERGENCY CHEMICAL SPILL RESPONSE LIVE OPERATOR 800.988.4424